Isigayo sepayipi esishiselwe i-ERW165

Incazelo Yokukhiqiza

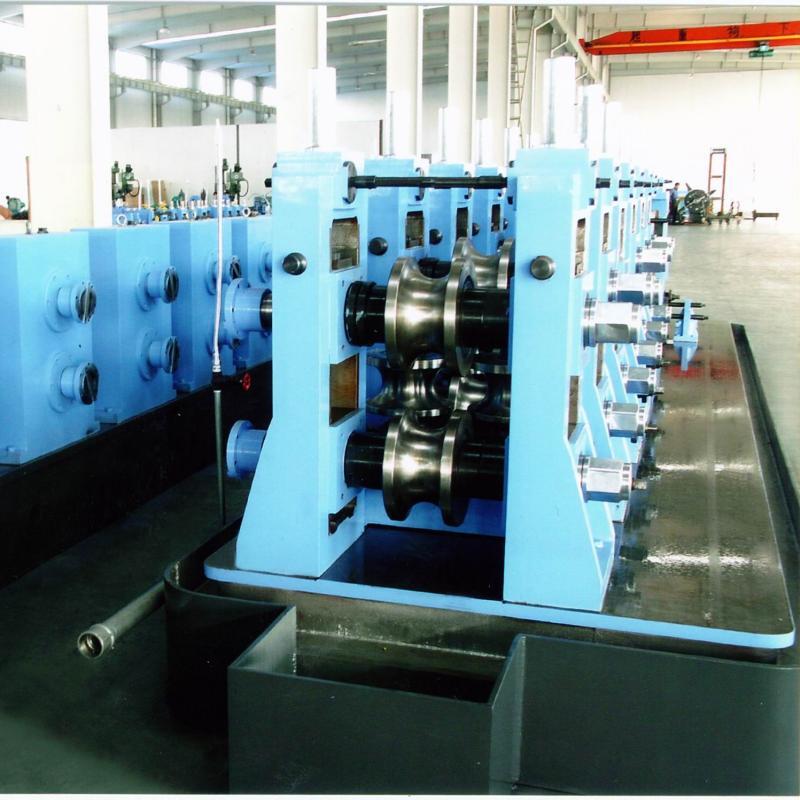

I-ERW165 Tube mil/oipe mil/ipayipi elishiselwe ukukhiqiza/umshini wokwenza amapayipi usetshenziselwa Ukukhiqiza amaphayini ensimbi angu-76mm~165mm ku-OD kanye no-2.0mm~6.0mm odongeni, kanye neshubhu eliyindilinga elihambisanayo, ishubhu yesikwele kanye neshubhu elimise okukhethekile.

Isicelo: Gl, Construction, Automotive, General Mechanical tubing, Ifenisha, Ezolimo, Chemistry, 0il, Gas, Conduit, Contructur

| Umkhiqizo | ERW165mm Tube Mill |

| Izinto Ezisebenzayo | I-HR/CR, Ikhoyili Yensimbi Yensimbi Ephansi Yekhabhoni, Q235, S2 35, Imivimbo ye-Gi. ab≤550Mpa, as≤235MPa |

| Ubude bokusika amapayipi | 3.0-12.0m |

| Ukubekezelela Ubude | ±1.0mm |

| Ubuso | Nge-Zinc Coating noma ngaphandle |

| Isivinini | Isivinini esikhulu:≤100m/min (ingenziwa ngezifiso ngokuya ngezidingo zekhasimende) |

| Abanye | Wonke amapayipi ashiselwe imvamisa ephezulu Kokubili ukugwaza okushiselwe ngaphakathi nangaphandle kuye kwaba isusiwe |

| Impahla ye-roller | I-Cr12 noma i-GN |

| Cindezela umqulu | H13 |

| Ububanzi bezinto zamapayipi ashiselwe | I-Hydraulic double-Mandrel un-coiler I-Hydraulic Shear&Automatic Welding Horizontal Accumulator Ukwakha & Ukulinganisa Umshini Uhlelo Lokulawula Ugesi I-Solid State HFWelder (AC noma DC Driver) I-Computer Flying Saw/Cold Cutting Saw Ithebula le-Run Out |

| Zonke izinto ezisetshenziswayo nezisetshenziswayo, njenge-uncoiler, motor, bearing, cut ting saw, roller, hf, njll., Zonke izinhlobo eziphezulu. Ikhwalithi ingaqinisekiswa. | |

Ukugeleza Kwenqubo

Ikhoyili Yensimbi→ Ikhoyili Yensimbi Enezingalo Ezimbili→Shicilela futhi Uqede Ukusika & Ukushisela →Isiqoqi Sekhoyili→Ukwakheka (Iyunithi Eflatelayo + Iyunithi Yokushayela Eyinhloko +Iyunithi Yokwakha + Iyunithi Yokuqondisa + Iyunithi Yokushisela Yokwehliswa Kaningi + Irola Yokukhama) → Ukucwenga →Ukupholisa Amanzi→Ukusika Nokuqondisa →Indlu Yokucathula →Indlu Ehamba Kade Isitoreji

Izinzuzo

1. Ukunemba Okuphezulu

2. Ukusebenza kahle kokukhiqiza okuphezulu, isivinini solayini singafika ku-130m/min

3. Amandla Aphezulu, Umshini usebenza ngokuzinza ngesivinini esikhulu, othuthukisa ikhwalithi yomkhiqizo.

4. Izinga lomkhiqizo Elihle Liphezulu, lifinyelela ku-99%

5. Ukumoshwa okuphansi, ukumoshwa kweyunithi okuphansi kanye nezindleko eziphansi zokukhiqiza.

6. Ukushintshwa okungu-100% kwezingxenye ezifanayo zemishini efanayo

Ukucaciswa

| Impahla eluhlaza | Ikhoyili Material | Insimbi Yekhabhoni Ephansi,Q235,Q195 |

| Ububanzi | 240mm-520mm | |

| Ubukhulu: | 2.0mm-6.0mm | |

| I-ID yekhoyili | φ580- φ700mm | |

| Ikhoyili OD | Ubukhulu:φ1800mm | |

| Isisindo sekhoyili | 5.0-6.0Amathani | |

| Amandla Okukhiqiza | Ipayipi elijikelezayo | 76mm-165mm |

|

| Ipayipi Eliyisikwele & elingunxande | 60*60mm-130*130mm 40*80mm-100*160mm |

|

| Ukuqina Kwezindonga | 2.0-6.0mm(Ipayipi Eliyindilinga) 2.0-5.0mm(Ipayipi eliyisikwele) |

|

| Isivinini | Ubukhulu.50m/min |

|

| Ubude bepayipi | 3m-12m |

| Isimo se-Workshop | Amandla Anamandla | 380V,3-isigaba, 50Hz (kuya ngezinsiza zendawo) |

|

| Amandla okulawula | 220V, isigaba esisodwa, 50 Hz |

| Ubukhulu bomugqa wonke | 85mX7m(L*W) | |

Isingeniso Senkampani

Kusukela ekuqinisekiseni okuphakathi, izingcezu zenhlama eyindilinga zishiyiwe noma zenziwa isicaba ngochungechunge lwamarola kulungiselelwa ukubunjwa kokugcina. Ishidi ngokuvamile liqukethe amasethi angu-2-3 (ochungechungeni) lwamakhanda e-roller agqinswe yi-Teflon okudluliswa phakathi kwawo ucezu lwenhlama ukuze kancane kancane lucaba inhlama.

I-Sheeting isebenzisa amandla okucindezeleka (ingcindezi) esiza i-degas inhlama yenhlama ukuze amangqamuzana omoya amakhulu athuthukiswe ngesikhathi sokudlulisa umkhiqizo noma ukufakazela ubufakazi obuphakathi ancishiswe abe amancane ukuze kuzuzwe okusanhlamvu okuhle kumkhiqizo oqediwe.

Amasethi ama-roller ahlelwa ngendlela yokuthi igebe/ukususwa kuncishiswe kancane kancane njengoba inhlama ihamba phakathi kwabo. Lokhu kubalulekile ukukhuthaza ukunciphisa okulawulwayo kokuqina kwenhlama. Ngeke kwenzeke ukucaba izingcezu zenhlama ngesinyathelo esisodwa ngaphandle kokudala umonakalo ongenakulungiseka ku-gluten nesakhiwo seseli yegesi.

Ngemva kokudlula kuma-roller aphezulu, ucezu lwenhlama luba luncane kakhulu, lube lukhudlwana, futhi luyi-oblong. Inhlama eyisicaba ephuma kuma-rollers aphansi isilungele ukudlula ngaphansi kweketango lokugoqa.